Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

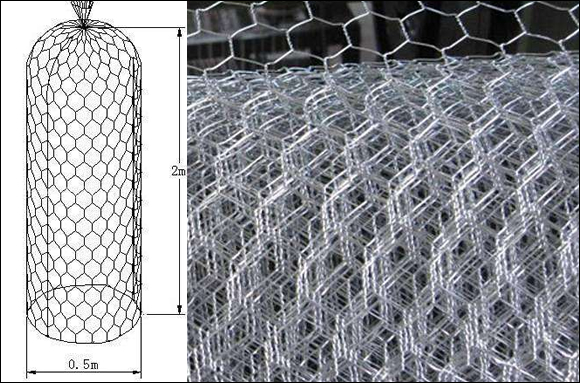

Sack Gabions- Gabion Mesh Bags - Sack Gabions Mesh Body Net

Sack gabions are made of woven wire meshes into a cylindrical container after being filled with stones to used like sacks or bags for river closure and bottoming. The sack gabions mainly includes a mesh body. After the mesh body is unfolded, the butterfly-shaped net surface is closed along the edge of the net body.

There is a polygonal mesh in the mesh body. The mesh is hexagonal. When the equipment is used for interception, the riprap can be thrown in a sack gabions bag. While increasing the roughness of the bottom of the ditch, it also improves the stability of the riprap and reduces losses. Each sack gabions can be removed as a whole, thus reduce the cost and difficulty of dismantling.

Sack Gabion Features

Sack gabions or mesh bags have the following advantages:

Sack gabions have strong impact resistance, strong integrity, good corrosion resistance and good flexibility, an easy adaptation to river bed deformation, and a popular use in key dangerous sections of deep water and rapid flow.

Sack Gabions for Flood Control Solutions

Due to the difference in construction conditions, different construction techniques and procedures are adopted along the river, where the water flow is gentle and affected by tidal floods, and gabion mesh bag throwing is carried out on the turbulent rivers and along the river, which was greatly affected by tidal floods.

Sack gabions construction:

Assembly: Lay the gabion mesh bag on a flat ground, flatten the excess creases, and spirally rotate it into a cylindrical shape along one side, and fix both ends with tie wires.

Basic preparation: The foundation of the sack gabions does not need to be too flat. For the wetland environment with poor foundation environment, gabion mesh bags can be used as a fixed platform. According to the needs of the project, fill in appropriate materials, and place sack gabions bags layer by layer. It should also be structured in accordance with engineering specifications. The geotextile can be clamped in each layer of gabion mesh bag.

Seam: The gabion mesh bag is rolled into a cylindrical mesh bag similar to a cloth bag with a mesh sheet, and is tied tightly with edge wire. Adjacent side meshes are wrapped with tie wires, as long as they are tied firmly on the side of the cylinder, and then the two bottoms are tightly wound, the gabion net bag can be used. When hemming, there should be an opening for loading stones on the cylinder surface. At the same time, when hemming and installing stones, care should be taken to protect the coating on the surface of the mesh to avoid damaging it.

Positioning: After tying up, use the machine to carefully hoist the gabion net bag once or twice, and put it into the proper position. In order to ensure the quality of the product, the thicker edge wire and tie wire are used for the seam and assembly of the gabion net bag.

Sack Gabions consist of a single mesh panel made of hexagonal woven wire Mesh Type 80, commonly referred as double twisted wire mesh. Sack Gabions are filled with rocks at the project site to form a flexible, permeable and monolithic structure. This structure is used for emergency and river training in works when local conditions require fast installation, or when the water does not allow easy access to the site or when underwater installation is necessary.

Filling and Lacing of Sack Gabions:

The Sack Gabion is assembled by rolling the mesh panel into a cylindrical shape and lacing the overlapped edges . Once one end of the cylinder is tied and laced closely, the Sack Gabion is filled with rocks ranging between 100 mm and 200 mm or any other material of suitable size. The range in sizes maybe from 80mm. 5% oversize or 5% undersize is also allowable, provided it is not placed at the exposed surface. In all cases, oversize rock should not be larger than 300 mm and the undersize rock should not be smaller than 100 mm. Rocks should be hard, angular, round and durable. So they shall not disintegrate on expose to water or weathering during the life of the structure. Care should be taken when placing the stone to ensure that the PVC coating on the Sack Gabion is not damaged. To expedite installation, two or more Sack Gabion can be tied together before installation. About lacing wire, lacing operation can be made by using certain tools available from our offices together with stainless steel rings.

The material used in the manufacture of Sack Gabions is heavily zinc coated steel wire. If necessary, a PVC coating is extruded over the galvanized wire to provide additional protection in aggressive environments. The PVC coating has a nominal thickness of 0,5 mm. The tolerances of mesh and wire are shown in Table 1 and Table 2. The end of the mesh has steel rods inserted during the manufacturing process to drive closing during installation. Dimensions and sizes of galvanized and PVC coated Sack Gabions are shown in Table 3. When specifying Sack Gabions in the tender documents or bill of quantities, please refer to Table 4.

Please refer to the following specifications:

Diameter: 3mm Tensile strength: 156-178 kg/mm2

Spacing of the rings or loops per specified.