Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabion Basket Hot Dip Galvanized

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Triple Twisted Wire Mesh Gabions

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

Gabions PVC Coated Galvanized Wire Box, Gabions for River Bank Retaining Wall in Bridge Construction - Gabions Wire, Galvanised with P.V.C. Coating

Gabions of galvanized wire boxes, with a P. V. C. coating ( coating of polyvinyl chloride ) are commonly used for river re-shaping in bridge and other construction projects. Green coating and grey coating at customers request.

PVC Coated Galvanized Gabion Mesh Products

Grey coated galvanized gabion box wire mesh

Mesh size:100mmx120mm

Finish: Grey coating after zinc coating

Wire:BS 1052-1986 standard tensile strength of not less than 350 Mpa.

Gabion Basket-PVC/Galvanised-Green Coated Galvanized Gabion Mesh

Specification:

PARTITION: 1

ZINC COAT: 260G/M2

MESH WIRE: 2.7MM

TIE WIRE: 2.2MM

MESH OPEN: 80MM x 100mm

SELVEDGE WIRE: 4.0MM

TENSILE STRNGHT: 380-550N/M2

Technical details of gabions material suitable river bank protection work

Technical details of Gabions wire, galvanizing, galvanised wire with P.V. C. coating ( properties including tensile strength, elongation, salt water exposure, durometer hardness, creeping resistance, resistance to abrasion and more tests), gabion mesh, selvedges, Diaphragms and End-Panels, binding and connecting wire, filling material, tolerances on wire diameter applied and gabions dimension.

.

1.1. General Introduction

The requirements as set out below for Gabions shall also apply to mattresses.

The gabions shall be flexible P.V.C. coated and galvanised wire boxes of the sizes stated and in this Specification fabricated of wire mesh of the type and size, and selvedged as specified below.

Each gabion shall be divided by diaphragms into cells whose length shall not be greater than the width of the gabion plus 100 millimetres, except in the case of 1.5 metre long by 1 metre wide gabions which have no diaphragm, 2.5 metre long by 1 metre wide gabions which shall have one central diaphragm, and Reno mattresses where the diaphragms shall have a maximum spacing of 600 mm.

1.2. Wire

All wire used in fabrication of the gabions and in the wiring operations during construction shall conform to BS 1052-1986 having a tensile strength of not less than 350 Mpa.

Unless stated otherwise on the Drawings or in any Special Provisions Addendum to this Specification, the wire used shall be 2.7 mm diameter, galvanised. The wire shall be PVC coated in accordance the specifications.

1.3. Galvanising

All wire used in the fabrication of the gabions and in the wiring operations during construction shall be galvanised to BS 443-1990 and the minimum weight of the zinc coating shall be according to the figures shown in the table below;

Diameter of Wire (mm) |

Weight of Coating (grams/sq.metre) |

3.9 |

290 |

3.4 |

275 |

3.0 |

275 |

2.7 |

260 |

2.4 |

260 |

2.2 |

240 |

2.0 |

240 |

The adhesion of the zinc coating to the wire shall be such that when the

wire is wrapped six turns round a mandrel of 4 times the diameter of

the wire, it shall not flake nor crack to such an extent that any zinc can

be removed by rubbing with the bare fingers.

1.4. P.V.C. Coating.

All wire used in the fabrication of the gabions and in the wiring operations during construction shall, after galvanising, have extruded on to it a coating of polyvinyl chloride, or “PVC.”

The coating shall be grey in colour, or dark green at options, in an average thickness of 0.55 mm and nowhere be less than 0.40 mm in thickness and shall be capable of resisting eleterious effects of natural weather exposure, immersion in salt water and shall not show any material difference in its initial properties listed below:

Initial Properties

(a) Specific Gravity

1.30 to 1.35, in accordance with ASTM D792-66(79)

(b) Durometer Hardness

50 to 60 shore D units in accordance with ASTM D2240-76 (ISO 868-1978)

(c) Volatile Loss

At 1050C for 24 hours - shall not be greater than 2%,

At 1050C for 240 hours - shall not be greater than 6%,

in accordance with ASTM 1203-67(74) (ISO 176-1976) and ASTM D2287-78

(d) Tensile Strength

210 Kg/cm2 in accordance with ASTM D412-75

(e) Elongation

Not less than 200% and not greater than 280% in accordance with ASTM D412-75

(f) Modulus of Elasticity

At 100% elongation:- not less than 190 Kg/cm2 in accordance with ASTM D412-75

(g) Resistance to abrasion

The loss of weight shall not be greater than 19g in accordance with ASTM D1242-56(75)

(h) Brittleness Temperature

Cold bend temperature shall not be greater than -300C in accordance with BS 2782 104A(1970) Cold flex temperature shall not be greater than +150C in accordance with BS 2782 150B(1976)

(i) Creeping Corrosion

Maximum penetration of corrosion of the wire core from a square cut end shall not be greater than 25 mm when the specimen has been immersed for 2000 hours in a 50% solution of HCI (hydrochloric acid 12 Be).

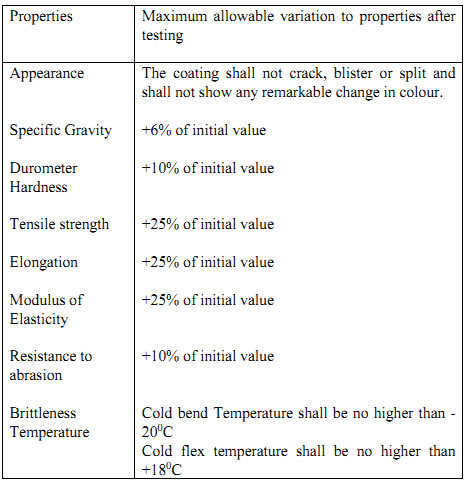

Table below lists the allowable variations to the Initial Properties after carrying out the following tests:-

(i) Salt Spray Test

As detailed in ASTM D117-73(79) for a test period of 1500 hours.

(ii) Exposure to Ultraviolet Light

As detailed in ASTM D1499-64(77) and ASTM F23-69(75) apparatus Type E for a test period of 2000 hours at 630C

(iii) Exposure at High Temperature

As detailed in ASTM D1203-67(74),(ISO 176-1976), and ASTM D2287-78 for a test period of 240 hours at 1050C.

Gabion Mesh

The mesh shall be hexagonal woven mesh wherein the joints are formed by twisting each pair of wires through two full turns. The wire used is to be as specified in Specification.

The undisturbed size of the mesh shall be 100 mm by 120 mm (the shorter dimension being taken from centre to centre of the parallel twisted joins and the longer dimension, which is nominal, being between the ends of the coaxial twisted joins). The tightness of the twisted joins shall be such that a force of not less than 1.75 kN pulling on one wire is required to separate it from the other, provided each wire is prevented from turning and the wires and the applied force are all in the same plane.

The wire mesh shall have elasticity sufficient to permit elongation of the mesh equivalent to a minimum of 10% of the length of the section of mesh under test without reducing the diameter or tensile strength of individual wire strands to values less than those for a similar wire 0.3 mm smaller in diameter.

Selvedges

All edges of the gabions, diaphragms and end-panels, except as stated in Sub-clause 1.7 of this Specification, shall be selvedged with a wire of which the core diameter is 3.4mm. Where the selvedge is not woven integrally with the mesh but has to be fastened to the cut ends of the mesh, it shall be attached by binding the cut ends of the mesh about it so that a force of not less than 8.5 kN applied in the same plane as the mesh, at a point on the selvedge of a mesh sample of length one (1) metre is required to separate it from the mesh.

Diaphragms and End-Panels

The diaphragms and end-panels shall be selvedged on the top and vertical sides only. The end panels shall be attached by twisting the cut ends of the mesh wires at the bottom of the panel about the selvedge on the base of the gabions. Similarly, the diaphragms shall be attached by twisting the cut ends of the mesh to the twisted joins of the mesh of the gabions. In each case the force required to separate the panels from the base shall not be less than that required to break the mesh over the same length.

Binding and Connecting Wire

Sufficient binding and connecting wire shall be supplied with the gabions to perform all the wiring operations to be carried out in the construction of the gabion work. The diameter of wire shall be 2.20 millimetres.

Filling Material

Filling material shall consist of hard, durable stone of minimum dimension 100 millimetres and maximum dimension 250 millimetres and shall be tightly packed to give a minimum of voids. The top layer of material shall consist of selected smaller stone of not less than 100 millimetres minimum dimension.

Tolerances ( Wire Diamter, Gabions Dimensions)

A tolerance on the diameters of all wire of + 2½ per cent shall be permitted. The length of the gabions is subject to a tolerance of + 3 per cent and the width of gabions to a tolerance of + 25 millimetres. All other gabion dimensions are subject to a tolerance of + 3 per cent of the sizes stated in this Specification.

For fabrication of gabions, placement, filling and forming of river banks and aprons, go to next page.