Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabion Basket Hot Dip Galvanized

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Triple Twisted Wire Mesh Gabions

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

Gabiony -Welded Mesh Gabions Cage-Woven Mesh Gabion Box

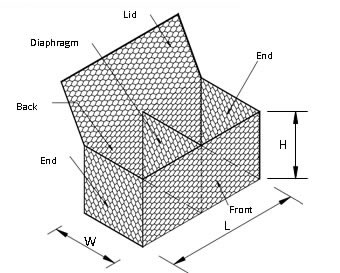

Gabiony is an element in the form of blocks made of wire mesh nettings of twisted hexagonal opening or welded square or rectangular openings, which is filled with natural stone for river, hill protection or construction.

The gabions shall be unfolded on the ground and stretched to the maximum extent possible while ensuring that all creases are in the correct positions for forming the box. Any cutting required shall be carried out so that the cut ends of wire are a minimum of 50 millimetres from the twisted joins. After stretching and cutting as required the side and end panels shall be lifted so that the tops of all sides are level. Any loose ends of wire protruding above a level plane at the top or from the corners shall be bent down into the box. Corners shall be fastened securely and the box shaped prior to commencing any binding.

Product Description:

Gabiony or gabion, is made of steel mesh with the type 8x10 mesh. The diameter of the wire mesh has normally two types: 2.7 or 3.0 mm. The gabion element is in the shape of block or regular cube size. These special wire bins are made of robust wire, filled with the vibrations at the quarry and transport are accompanied by the lifting straps.

Technical Specifications:

Gabions sizes: 2m x 1m x 1m, 3m x 1m x 1m, 4m x 1m x 1m, 2m x 1m x 0.5m, 4m x 1m x 0.5m. Custom orders available.

Finish can be hot-dipped galvanized, galvanized aluminum alloy or PVC coated, etc.

Applications:

Gabiony is mainly used in the following fields:

Building blocks of gravity walls

Forming of gravity walls

Reinforced structure (a combination of reinforcing wire mesh containers)

Control and guide of water or flood

Flood bank or guiding bank

Preventing of rock breaking

Water and soil protection

Bridge protection

Strengthening structure of soil

Protection engineering of seaside area.

Gabiony is a kind of box structure filled with stones to protect slopes, or make retaining walls. According to the different production processes, it is divided into two types: welded gabions and woven gabion. The products produced by these processes have their own characteristics and applications.

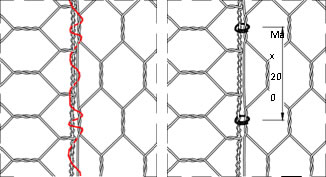

Gabions of PVC coated mesh and binding wire

Galvanising shall be in accordance with BS EN 10244 and shall withstand 220 hours of exposure to salt spray test before failure by rusting. Wire mesh shall comply with BS EN 10223 and the maximum mesh size, measured across the twisted wire flats shall be as indicated

Wire for Gabiony Construction

Gabion Wire Types |

Diameter (mm) |

Galvanising (g/m ) |

Mesh Box Mattress Binder Box Mattress |

3.4 2.7 2.2 2.2 |

275 260 240 240 |

Selvedge Box Mattress |

3.9 3.4 |

290 275 |

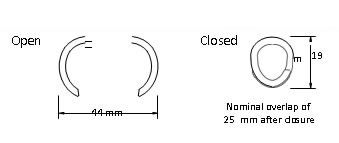

Figure 1

Figure 1

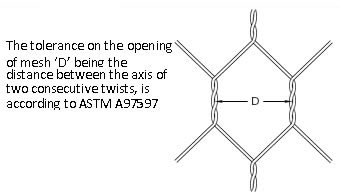

Figure 2

Figure 2

Figure 3

Figure 3

Figure 4

Figure 4

Welded Mesh Gabiony Cage Characteristics

Gabions made of electro-spot-welded, steel-wire mesh-grids with curved and welded eyelet and locking rod, locking system with minimum risk of injury.

Range of application:

Slope stabilization, noise barrier, blinds, landscaping, facing-element of (plastic-) reinforced soil field of application

Lap welding process where warp and weft intersect;

The mesh of the gabion cage is rectangular, square or rhombus shape;

The panel cannot be deformed: due to the spot welding process, the panel is flat and cannot be folded and deformed;

The mesh size can be changed: the spot welding process can adjust the distance between the two steel wires, resulting in a change in the mesh size.

Mesh Grids:

sizes mesh size: wire size: tensile strength: |

200x100cm, 200x50cm, 150x100cm, 150x50cm 100x100cm, 100x50cm, 50x50cm differing sizes on request 10x10cm und 5x10cm differing mesh sizes on request 4,5mm und 5,0mm min. 450 N/mm² |

sizes: wire size: tensile strength: |

50 cm, 100cm, 150cm, 200cm 6,0mm min. 450 N/mm² |

sizes: wire size: tensile strength: |

50cm, 100cm, 150cm 5,0mm min. 450 N/mm² |

Corrosion Protection:

By means of applying a firmly adhering zinc-aluminium alloy (Zn 95% / Al 5%) on the steel, a good visiual appearance with optimal corrosion protection is achieved.

Thus achieves a much longer durable corrosion protection compared to a pure zinc galvanizing.

Features of double twisted steel wove gabion boxes

Weaving characteristics: When weaving, two steel wires are entwined with each other, and then entangled with other steel wires after being separated to form a gabion mesh with hexagonal mesh;

The stranding length is controllable: when the two steel wires are twisted, the stranding length can be changed to avoid the two steel wires from squeezing each other during the winding process;

The number of twisting is variable: when two steel wires are twisted, the three wire process can be selected. The three twist process is that two steel wires are wound three 180 degrees in one direction.

Folding process: The gabion cage is folded from gabion mesh, and the flexible feature of the winding enables the gabion mesh surface to be folded and deformed;

Flexibility structure: The mesh has a hexagonal structure.

Specification of Hexagonal Wire Netting Materials

spec. of wire mesh |

max. twistable wire diameter |

max. mesh width |

||

mesh no |

mesh size |

galv.wire |

pvc covered wire |

- |

2-1/2" |

60x80 mm |

BWG12 (2.80mm) |

4.0mm |

3200 mm |

3" |

80x100 mm |

BWG11 (3.00mm) |

4.0mm |

4000 mm |

4" |

100x120mm |

BWG11 (3.00mm) |

4.0mm |

4000 mm |

Sizes of Gabiony:

2x1x1m; 3x1x1m; 4x1x1m; 5x1x1m; 6x1x1m; 3x1.5x1m; 4x2x1m; 5x2x1m;

2x1x0.5m; 3x1x0.5m; 4x1x0.5m; 5x1x0.5m; 6x1x0.5m; 3x1.5x0.5m; 4x2x0.5m; 5x2x0.5m